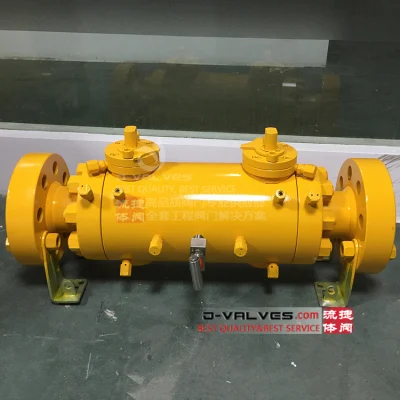

Forged A105 Pump Protection Valve

Vatac Automatic Recirculation Valve is a kind of pump protection device. It automatic protect centrifugal pump when pump

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | BBH41F |

| Type | Floating Ball Valve |

| Function | Blow-Down Valve |

| Temperature | Normal Temperature |

| Application | Industrial Usage, Water Industrial Usage, Household Usage |

| Inspect & Test | API 598 |

| Ends Connection | Flange RF or Rtj |

| Certificate 2 | ISO 9001: 2008 |

| Certificate 1 | Dnv Ce 0575 |

| Pre-Temp. Rating | ASME B16.34 |

| Face to Face | ASME B16.10 |

| Design & Manufacture | API 6D, ASME B16.34 & BS5351 |

| Characteristic | Pump Protection |

| Transport Package | Sea Worthy |

| Specification | API, ANSI, ASME, DIN, JIS etc. |

| Trademark | VATAC |

| Origin | China |

| HS Code | 84818010 |

| Production Capacity | 6000ton Per Year |

Product Description

Vatac Automatic Recirculation Valve is a kind of pump protection device. It automatic protect centrifugal pump when pump body occur cavitations damage or unstable (especially conveying hot water at low load operation medium). Once pump flow is lower than the preseted flow, bypass can completely open to ensure the minimum required flow pump. Even running fully closed, namely running flow is zero, the minimum flow can also pass bypass for Automatic Recycle. Pressure reduced through the multistage bypass pressure reducing valve.Vatac Pump Protection Valve is suitable for bypass with high pressure differential, maximum pressure differential is 30MPa, and specific choice is determined by factory. Multistage decompression type M type bypass can eliminate noise made by high-speed flow medium; prevent damage of cavitations erosion and braising to valve components.

Vatac Pump protection valves (automatic recirculation valve) are with main features as below:

» Nominal Diameter: 1"~12"

» Engineering Pressure: CL150~900

» Bypass Size: 1/2DN (standard); or special

» Recommended Flow Rate: 4 to 6 m / s up to 8 m / s

» Ends Connections: Flanged (ANSI or DIN)

» Main Body Materials: cast steel, forged carbon steel, beryllium cast chrome-nickel-molybdenum stainless steel, chrome-nickel-molybdenum-beryllium steel forging

» Trim Material: chrome steel, forged chrome-nickel-chromium-molybdenum stainless steel

1. Construction is as follows

| - Full Port or Reduce Port | |||

| - One Piece or Split Body | |||

| - Bolted Bonnet with spiral-would gasket | |||

| - Fire Safe Design | |||

| - Anti-static Design & Blow-out proof stem | |||

| - Socket Weld Ends to ASME B16.11 | |||

| - Butt Weld Ends to ASME B16.25 | |||

| - Screwed Ends to ANSI/ASME B1.20.1 | |||

| - Flanged Ends to ASME B16.5 |

2. Main Part & Materials

| Part Names | Part Materials | ||||||

| Body | WCB/A105 | LCB/LF2 | WC6/F22 | CF8/F304 | CF8M/F316 | CF3/F304L | CF3M/F316L |

| Bonnet | WCB/A105 | LCB/LF2 | WC6/F22 | CF8/F304 | CF8M/F316 | CF3/F304L | CF3M/F316L |

| Ball | A105+ENP | SS304 | F22 | SS304 | SS316 | SS304L | SS316L |

| Stem | A105 | F304 | F6a | F304 | F316 | F304L | F316L |

| Seat/Seat Ring | PTFE/RPTFE/NYLON/DEVLON/PEEK or METAL | ||||||

| Packing | Graphite/PTFE | ||||||

| Gasket | SS304+Graphite/SS316+Graphite | ||||||

| Bolts/Nuts | B7/2H | L7/4 | B16/4 | B8/8 | B8M/8M | B8/8 | B8M/8M |

| Suitable Medium | W.O.G etc. | HNO3, CH3OOH etc. | |||||

| Suitable Temperature | -29~425 °C | -46~340 °C | -46~340 °C | -196~427 °C | -196~427 °C | -196~427 °C | -196~427 °C |

3. Normal Pressure Rating

PN10~PN420, CLASS150~2500

4. Normal Size Range

DN15~DN100, 1/2"~4"

5. Pictures

Final Inspection

Shipping